Can you tell us about your background and experience before Volta Trucks.

I was a mature graduate in Mechanical Engineering as I spent eight years racing on the Norwegian National Alpine Team and on the US Pro Tour. I started work in food & beverage as a Project Manager building Coca-Cola plants in Poland and bottling Plant Manager in Norway. I got the opportunity to take an MBA at INSEAD, France, from where I joined a Manufacturing Leadership Program at Ford headquarters. I had various assignments around Europe including Launch Manager, Assembly Plant Manager and Strategy Manager. I then returned to Scandinavia and Volvo Cars where I ran the Manufacturing Business Office for many years, including three years in China supporting the early phases of building three plants in three years. Returning from China, I had responsibility for Manufacturing and Purchasing in the newly created Polestar brand – Volvo’s new electric performance marque. Once the new Polestar plant in China started production, I left and co-Founded Volta Trucks.

You’re co-Founder of Volta Trucks as well as Chief Technology Officer – how did you meet the founder, Carl-Magnus Norden and what was that journey like?

While working on starting up Polestar, I met Carl-Magnus through the INSEAD alumni association. He asked for advice on the possibility of starting an electric truck company. The idea was crazy enough to catch my interest, and soon I realized he was onto something. We had witnessed an enormous start-up activity in electric passenger cars, enabled by the disruptive technology change. However, the same activity hadn’t yet started for trucks, so it was natural to assume there was an opportunity available for early movers. We decided to go for the city centre distribution and last-mile segment, partly because it seemed untouched and partly because we saw an immense demand for clean, silent trucks in the cities. And we soon realized the opportunity that the electric powertrain provided to make a step change in safety and driver attractiveness. To capture the early mover advantage, we set off very quickly. It took us just a few months from the start of concept development until the building of the demonstrator had started, and just another six months until it was finished, all during the peak of the pandemic! When launched, the demonstrator vehicle received a tremendous reception amongst customers and media, in turn securing funding for the full development of the vehicle and the company. We were about 10 employees last Christmas, now we are 150, and we have 93 open positions on our website! The speed seems to be accelerating every week! It’s exhilarating!

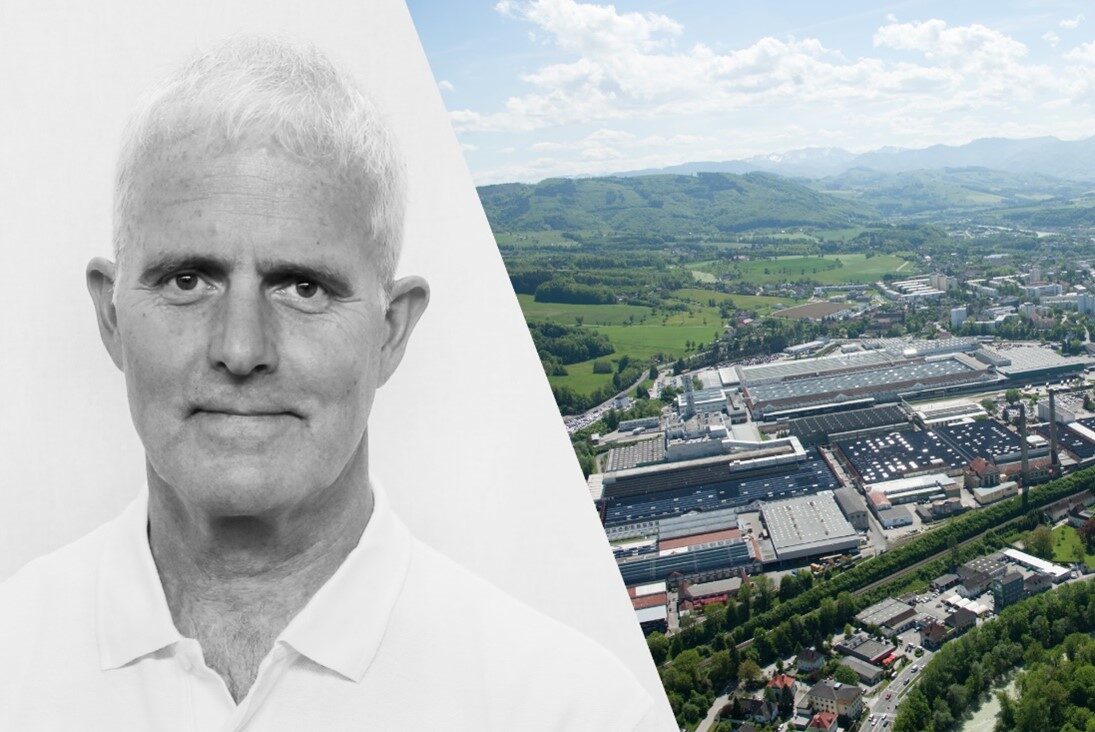

As Chief Technology Officer, you are primarily responsible for manufacturing for Volta Trucks, and you’ve just announced that the first Volta Zero vehicles will be built by Steyr Automotive. What was the selection process like?

We started the search and selection process almost immediately, while developing the vehicle concept. A solid manufacturing partner would be critical, and in line with the ambition to be quick to market, it was clear that we would not have time to build our own plant. At the same time, we weren’t really keen on asking the incumbents for cooperation. For a long time, we were looking for potential contract manufacturing partners in the bus market because our truck design turned out to be more like a bus than a conventional truck. Just when we were getting close to the deadline for plant selection, the MAN plant in Steyr, Austria came on the contract manufacturing market. It was incredibly good timing, it is a perfect match for us, better than we could have dreamt for in the beginning!

Can you describe the selection criteria that you were focused on to find the right partner?

The most important factors were risk reduction and speed to market. To enable this, availability of facilities, skills and experience in the workforce and readiness to support in our global expansion, were critical components, as well as cost, of course.

At the launch of the Volta Zero, there was discussion about manufacturing in the UK, and you also announced an option to manufacture in Barcelona. Are these still options? Was Brexit an issue for UK candidates?

Since the engineering and prototype build was done in the UK, we did of course investigate manufacturing opportunities in the UK. However, due to the strength of the other candidate sites the UK alternatives lost out in the end. Brexit was never an issue in the selection process. Barcelona became a potential candidate when the car plant closure there was announced. However, it was less well suited for being our first plant, as it was a car plant and needed significant reconfiguring and wouldn’t therefore be available on time.

What next – how do you move from contract signing to manufacturing actual vehicles in the very tight timescales you’ve set yourselves?

We are now in the process of joining hands with the Steyr team in planning the details. The first big equipment orders will go out in about a month, and installation starts in the spring. The first trucks will be built in the plant in June next year and series production starts by the end of next year. It is a very tight schedule, requiring experienced and committed personnel at all levels.

What about the longer term – you’ve talked about manufacturing vehicles close to where they’ll be sold, and you’ve named the US as an interesting market. Does this mean that we’ll see a number of Volta Trucks manufacturing plants across the world in due course?

Yes, that is the plan. The electrification drive spreads like wildfire, and the demand is skyrocketing everywhere. We’ve had requests for vehicles from all corners of the world already. We are designing a global roll-out plan that will be possible to do with minimized risk and cost and at maximum speed. If all goes to plan, we will be serving most of the major markets throughout the world within a few years.